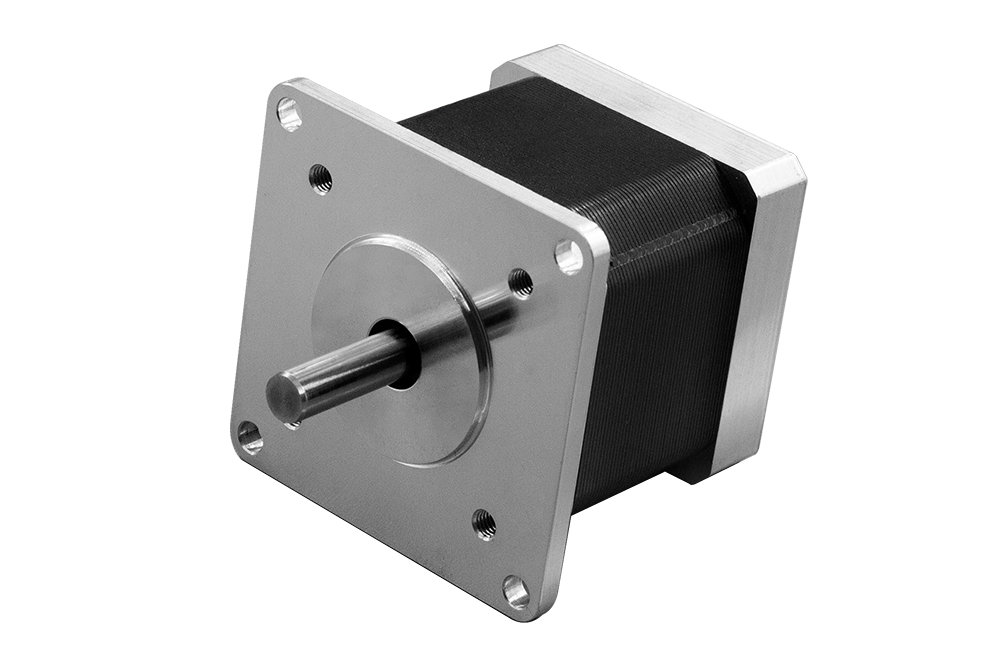

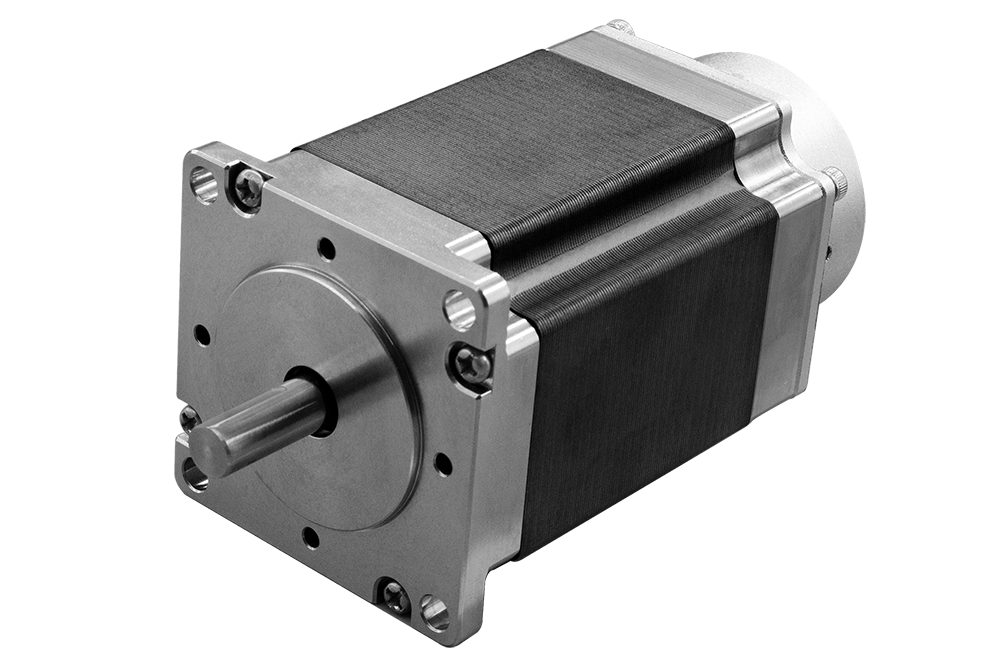

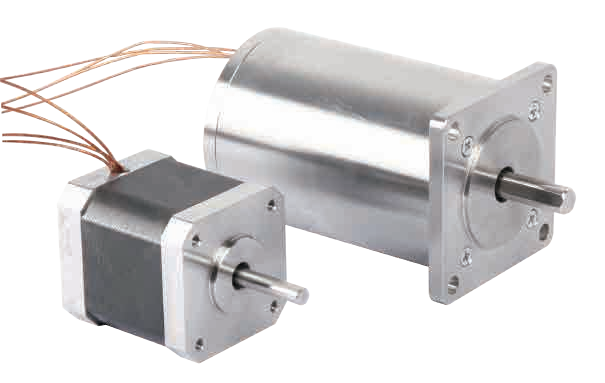

Vacuum Stepper Motor

Vacuum Rated Stepper Motor

l use in vacuum/high/low temperature environments

l Vacuum level: Max. 1.0x10-7Pa

l Radiation resistant: 106Gy

l Low outgassing

l Optimized power consumption

l Heat dissipation provisions

l Withstand temperature range from-196C to+200C

l Low vibration generation

l High amplitude vibration tolerance

l Complete component origin traceability

Our Vacuum Rated Stepper Motor will be installed in a clean room, vacuum chamber, or perhaps go into space. Electrical equipment is difficult to operate in a vacuum environment, of course, this also includes stepper motors. Traditional stepper motors can not be used in a vacuum environment there are two factors: heat and contaminants.

Heat is generated when the coils of the motor are energized. In normal operation, air acts as a conductor and radiates heat. There is a lack of conductors in a vacuum because of the lack of air. Our engineers will solve such problems and have learned to wind our motors specifically for vacuum applications.

Contaminants--At the microscopic level, gas is shown to be trapped in paints, coatings and oils. When the environment becomes a vacuum, the gas trapped inside the motor expands, and unwanted contaminants introduced. Now we are using low-outgassing materials in the design and manufacture of vacuum-rated motors, we reduce outgassing efficiently.

Temperature Management

Reduced motor performance and shortened motor life will greatly affect the efficiency of the entire system. The main problem faced by motors operating in a vacuum environment is the heat generated by the coils.

Because of the heat generated in the work, the magnetic field strength of the permanent magnet will be affected, and the magnetic field strength will decrease at the same time, the motor torque will also be affected, and the motor will even stop running when the heat is too large. At the same time, motor bearings are also affected by heat.

Although the traditional motor design takes into account heat convection, because in a vacuum environment, there is no air, the motor will accumulate a lot of heat during operation and thus destroy the motor.

Our engineers used magnets made of high temperature resistant alloys, and bearings with greases rated from -80°C to 204°C. We use a specific winding formulation in the design of the vacuum motor, which will generate less heat and provide excellent sustainability in a vacuum of up to 10-7 Torr at 110°C.

Outgassing and Contaminations

Sensors and sensitive instruments will be affected by contaminants inside the engine. Mainly because of the expansion of trapped gas inside the engine caused by pollutants into the environment. Venting must be avoided in a vacuum environment. Our vacuum rated motors are designed to minimize outgassing.

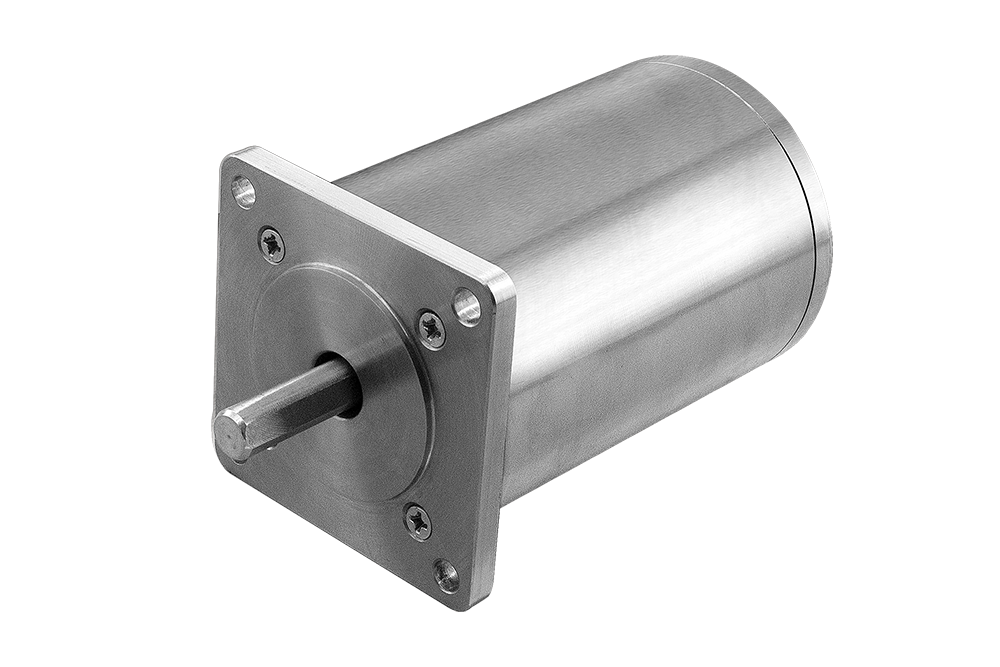

The motor components (end caps, stators, rotors and screws) are made of low outagassing material. At the same time, we also designed special sealed bearings. All components are cleaned and vacuum baked, and assembled in a dust-free environment. We use vacuum sealed packaging to ensure that the entire process is free of contaminants.

We will customize for you:

Vacuum Degree | HV <10-5Pa | optional |

UHV >10-5Pa | optional | |

Temperature Range(°C) | NT -20 ~ +85 | optional |

NT -40 ~ +85 | optional | |

NT -60 ~ +85 | optional | |

HT -20 ~ +150 | optional | |

SHT -20 ~ +200 | optional | |

LT -100 ~ +40 | optional | |

SLT -196 ~ +40 | optional | |

RA: Radiation resistance | optional | |

TS: Temperature sensor | optional | |

B: With brakes | optional |

|