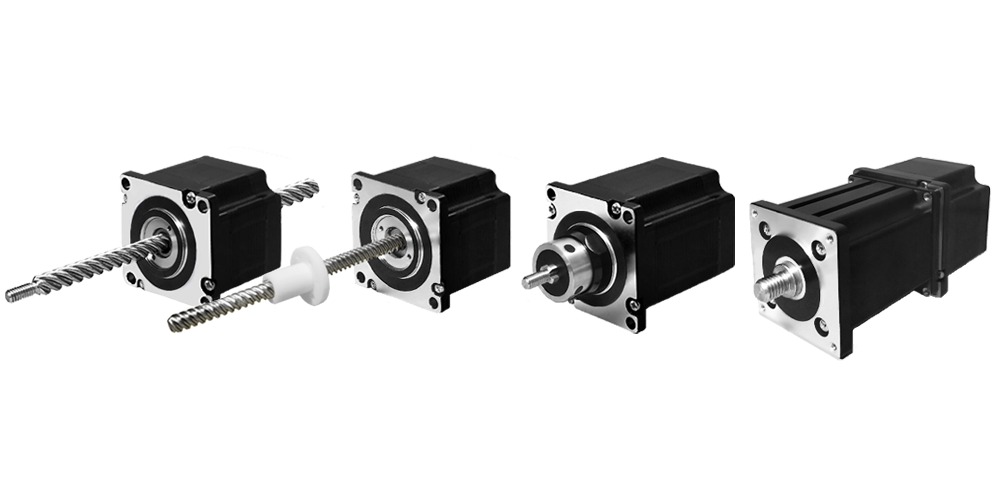

Size 24 [60mm] provides high performance, a longer working cycle, and is capable of 1050N.has four form factors available - External, Non-Captive, Electrical Cylinder (Captive) and Kaptive.

Motor Characteristics

| Motor | Voltage[V] | Current[A] | Resistance[Ω] | Inductance[mH] | Weight[g] | Lead Wire No. | Motor Length[mm] |

|---|---|---|---|---|---|---|---|

| 24-2120 | 3 | 2 | 1.5 | 3.9 | 680 | 4 | 47 |

| 24-2130 | 1.8 | 3 | 0.6 | 1.6 | 680 | 4 | 47 |

| 24-2140 | 1.6 | 4 | 0.4 | 0.9 | 680 | 4 | 47 |

| 24-2230 | 3 | 3 | 1 | 3.4 | 1080 | 4 | 68.3 |

| 24-2240 | 2.4 | 4 | 0.6 | 1.9 | 1080 | 4 | 68.3 |

| 24-2250 | 1.5 | 5 | 0.3 | 1.2 | 1080 | 4 | 68.3 |

NOTE

Motor Insulation Class B, Motor Temperature Rise 80°C, Ambient Temperature -20℃~55℃

Available Lead Screw and Travel per Step

| Screw Dia.[inch] | Screw Dia.[mm] | Lead[inch] | Lead[mm] | Lead Code | Travel Per Step @ 1.8° [mm]* | Travel Per Step @ 0.9° [mm]* |

|---|---|---|---|---|---|---|

| 0.375 | 9.525 | 0.025 | 0.635 | A | 0.0032 | 0.0016 |

| 0.375 | 9.525 | 0.05 | 1.27 | D | 0.0064 | 0.0032 |

| 0.375 | 9.525 | 0.0625 | 1.5875 | F | 0.0079 | 0.004 |

| 0.375 | 9.525 | 0.083 | 2.1167 | H | 0.0106 | 0.0053 |

| 0.375 | 9.525 | 0.1 | 2.54 | K | 0.0127 | 0.0064 |

| 0.375 | 9.525 | 0.125 | 3.175 | L | 0.0159 | 0.0079 |

| 0.375 | 9.525 | 0.167 | 4.2333 | P | 0.0212 | 0.0106 |

| 0.375 | 9.525 | 0.2 | 5.08 | R | 0.0254 | 0.0127 |

| 0.375 | 9.525 | 0.25 | 6.35 | S | 0.0318 | 0.0159 |

| 0.375 | 9.525 | 0.375 | 9.525 | V | 0.0476 | 0.0238 |

| 0.375 | 9.525 | 0.384 | 9.7536 | W | 0.0488 | 0.0244 |

| 0.375 | 9.525 | 0.4 | 10.16 | X | 0.0508 | 0.0254 |

| 0.375 | 9.525 | 0.5 | 12.7 | Y | 0.0635 | 0.0318 |

| 0.375 | 9.525 | 1 | 25.4 | Z | 0.127 | 0.0635 |

| 0.394/0.472 | 10/12 | 0.0787 | 2 | G | 0.01 | 0.005 |

| 0.394/0.472 | 10/12 | 0.3937 | 10 | C | 0.05 | 0.025 |

| 0.394 | 10 | 0.7874 | 20 | I | 0.1 | 0.05 |

| 0.472 | 12 | 0.1969 | 5 | E | 0.025 | 0.0125 |

* Value truncated

* Motor winding and screw lead could be customized according to customer's request

* 15.875mm diameter screw only can be applied in External Type

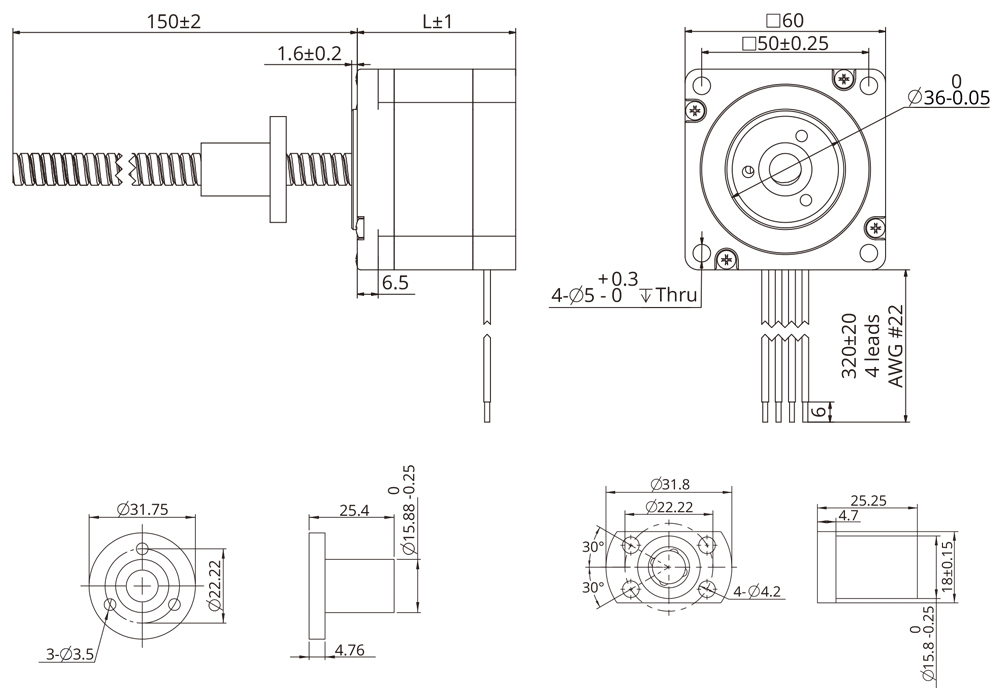

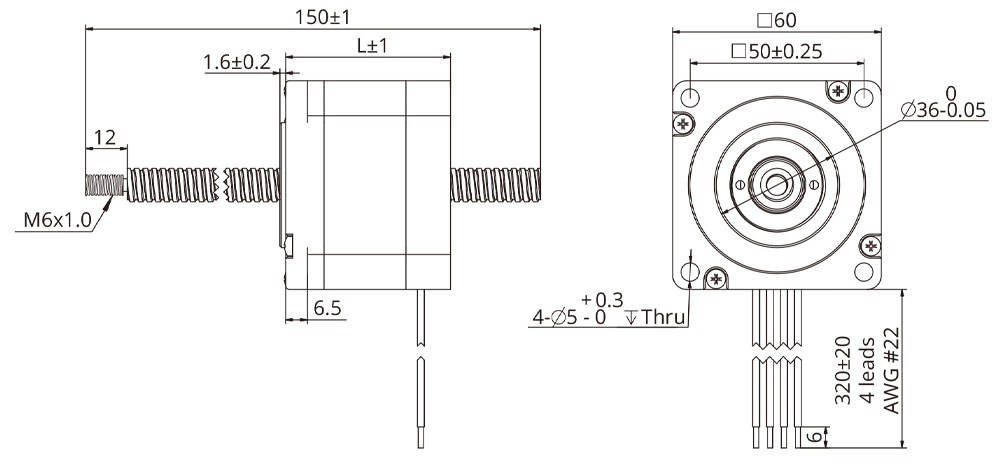

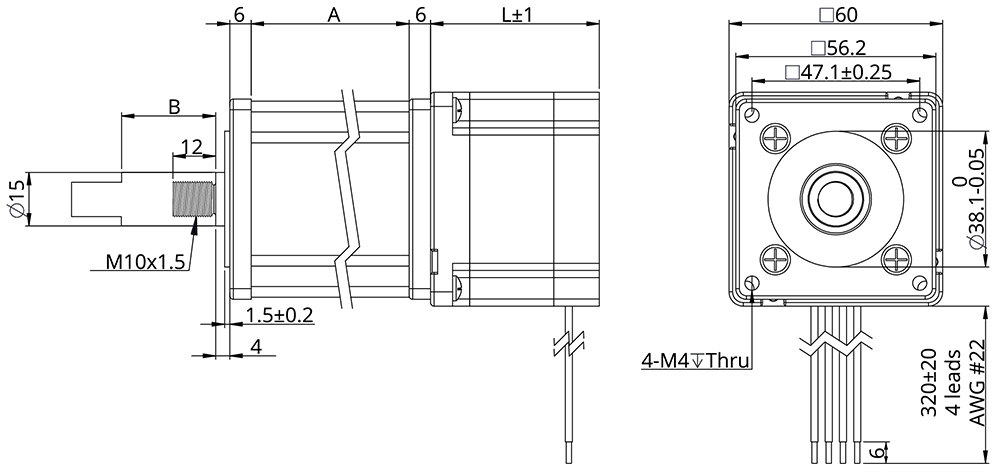

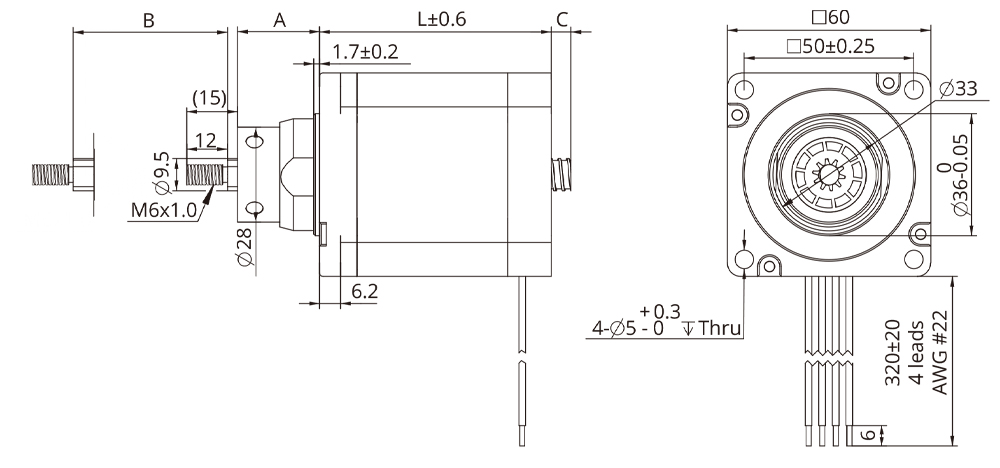

Dimensional Drawings

External

Non-Captive

Captive

Stroke Specification

Size A

(mm)Stroke B

(mm)Size L (mm) 45.70 12.70 Single Stack

Motor

47Double Stack

Motor

68.352.05 19.05 58.40 25.40 64.80 31.80 71.10 38.10 83.80 50.80 96.50 63.50 Kaptive

Stroke Specification

Size A

(mm)Stroke B

(mm)Size C (mm) Single Stack

L=47Double Stack

L=68.324.20 12.70 5.8 0.00 30.55 19.05 12.15 2.15 36.90 25.40 18.5 8.50 43.25 31.75 24.85 14.85 49.60 38.10 31.2 21.2 62.30 50.80 43.9 33.90 75.00 63.50 56.6 46.60 Speed Thrust Curves

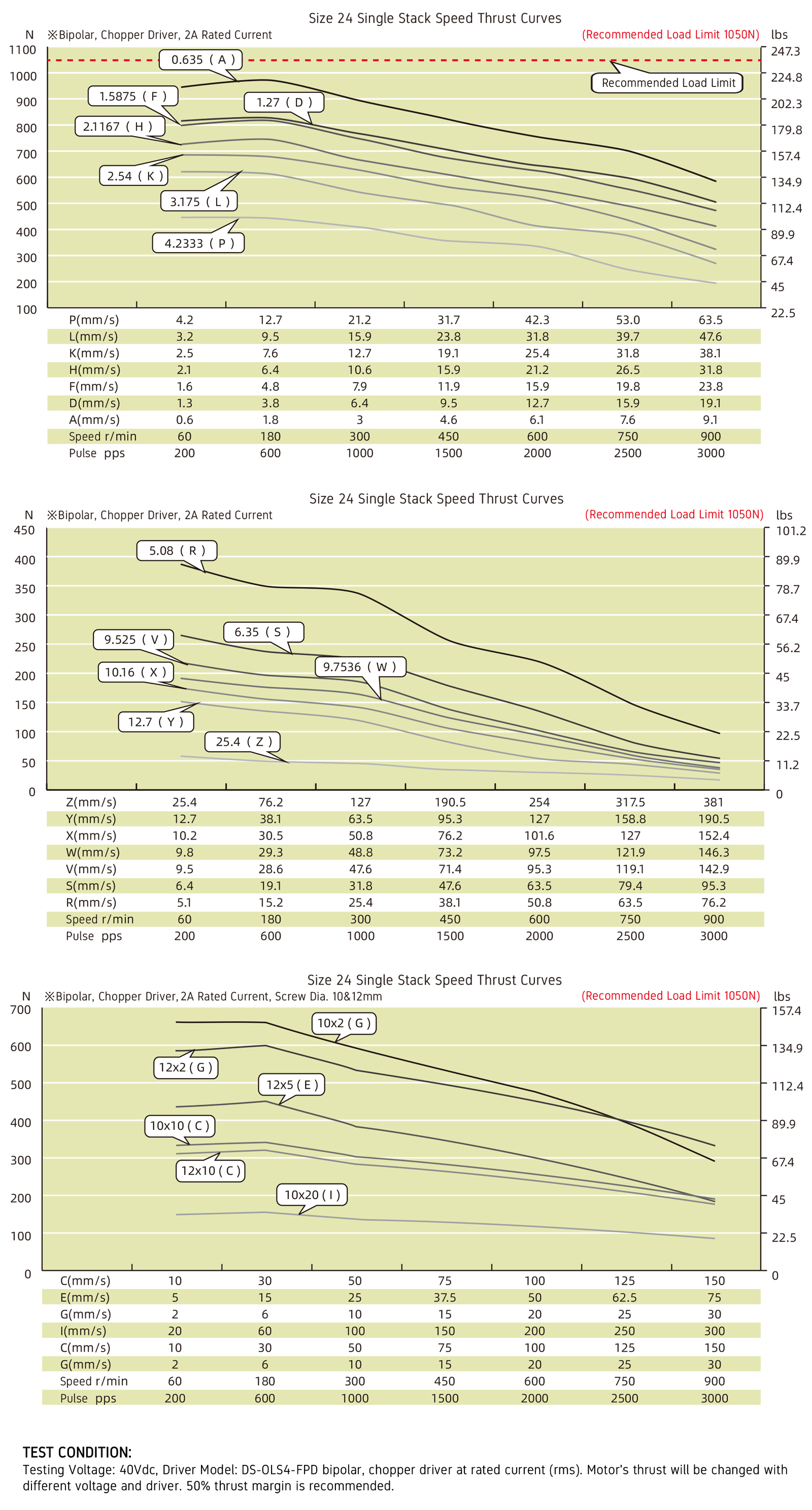

Single Stack

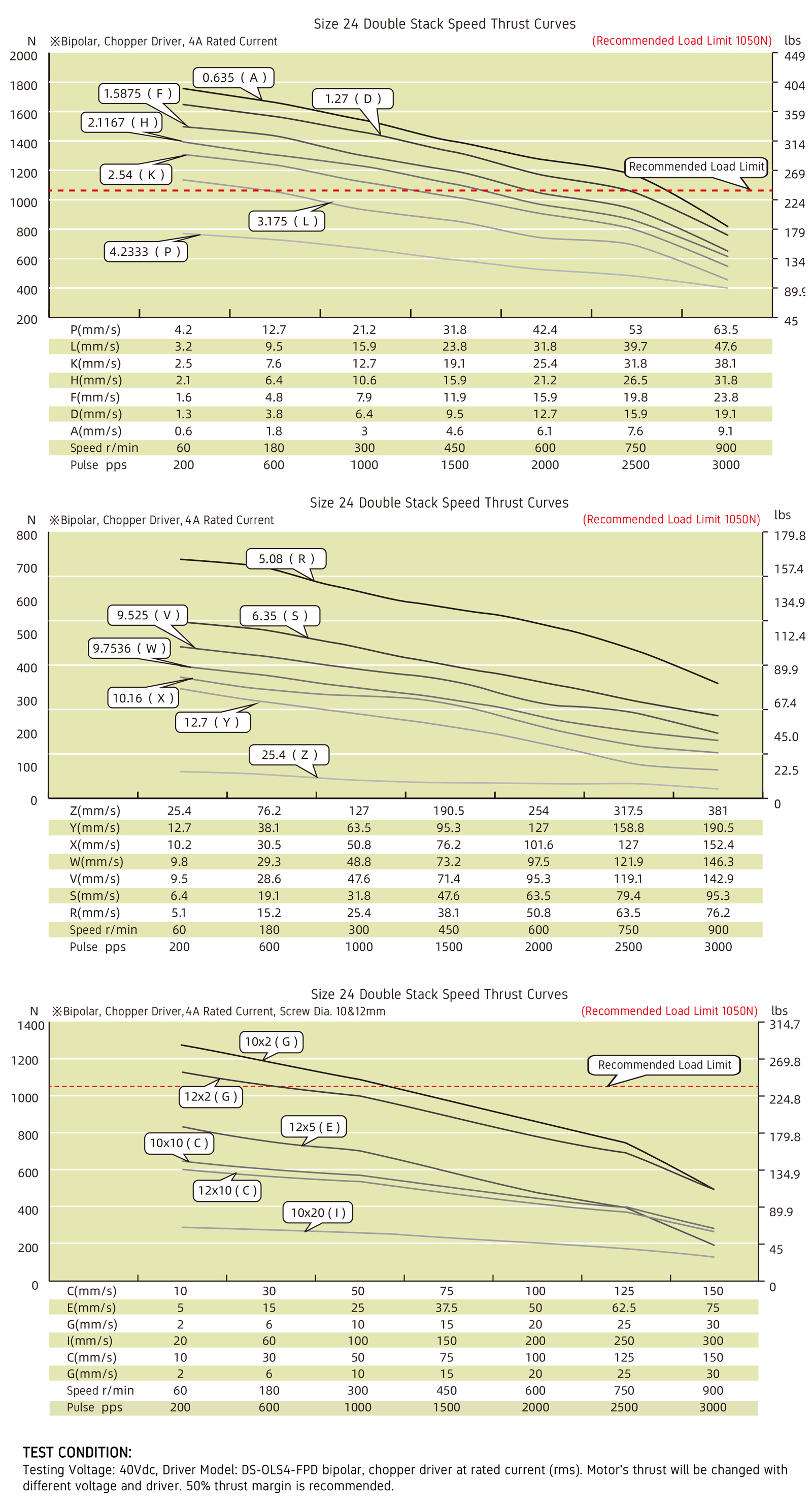

Double Stack

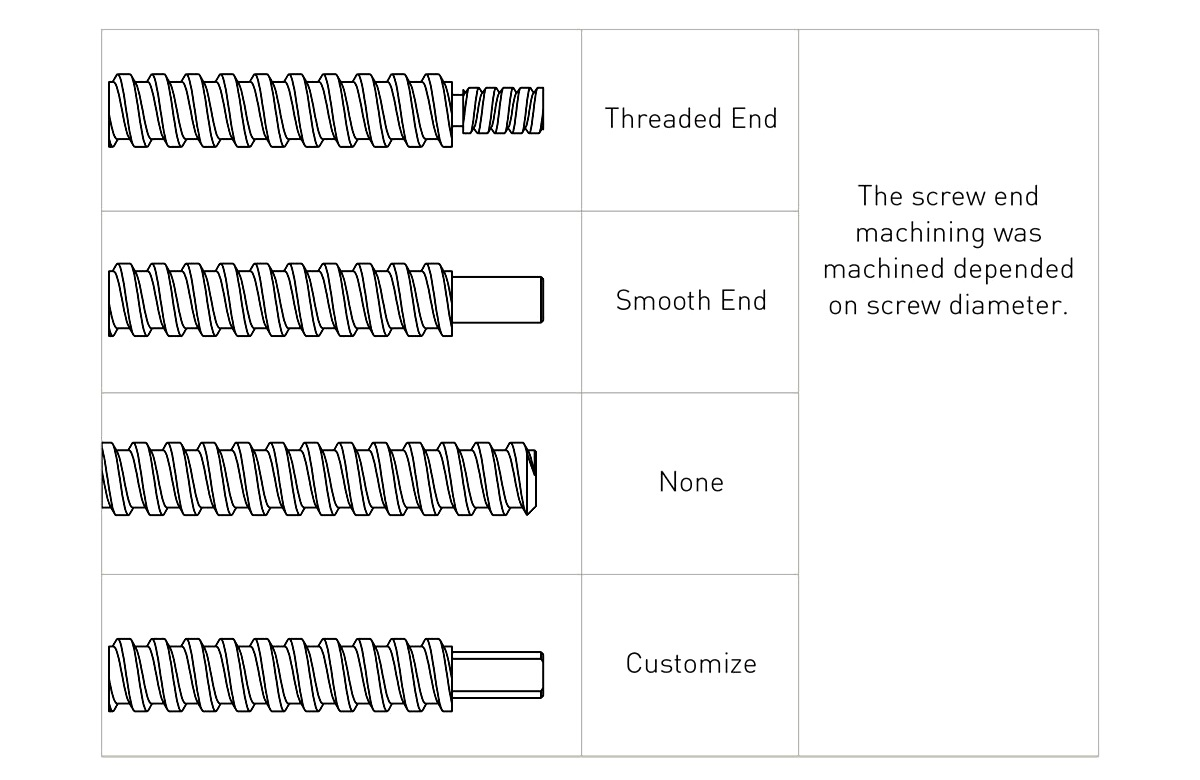

Options

Screw End Machining

Teflon Coating

If customer's applications require greaseless screw and nut combination,we offer teflon coated lead screw of stepper linear actuator.

Teflon coated lead screw stepper linear actuator enables it's longer life cycle and better thrust force generation against conventional SUS lead screw.

Teflon coating can be applied in the whole range of lead screw options and all types of linear actuators such as External, Non-Captive, Electric Cylinder and Kaptive.

In addition, anti-backlash nut also can be combined with teflon coated lead screw too.

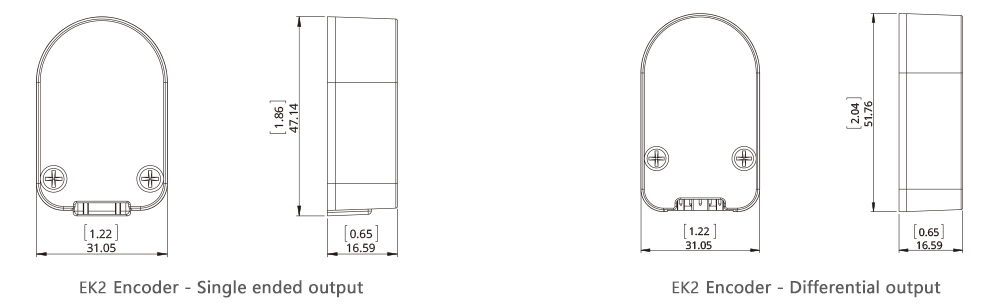

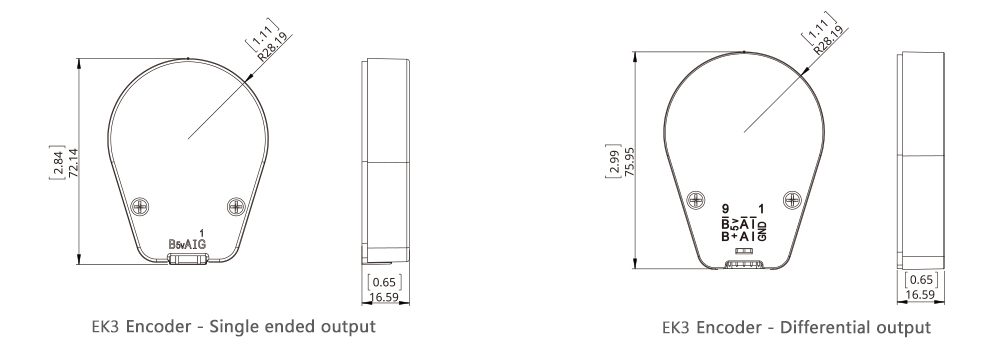

Encoder Option

| Resolution(CPR) | 50 | 100 | 192 | 200 | 250 | 256 | 360 | 400 |

| Single ended output | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| Differential output | A | B | C | D | E | F | G | H |

| Resolution(CPR) | 500 | 720 | 900 | 1000 | 1250 | 2000 | 2500 | 4000 | 5000 |

| Single ended output | 8 | 9 | 10 | 11 | 12 | ||||

| Differential output | I | J | K | L | M | N | O | P |

Resolution(CPR) 64 100 200 500 1000 1800 2000 Single ended output 0 1 2 3 4 5 6 Differential output A B C D E F Resolution(CPR) 2500 3600 4000 5000 7200 8000 10000 Single ended output 7 8 Differential output G H I J K L M

* EK3 Encoder is only available for NEMA 24 (60mm) Non-Captive, Captive, Kaptive linear actuator.

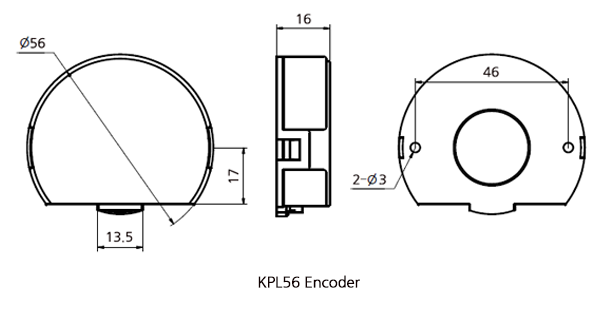

Resolution(CPR) 400 800 1000 1250 1600 2000 2500 3200 4000 Single ended output 0 2 3 4 5 6 7 8 9 Differential output A C D E F G H I J Power-Off Brake

Power Off Brake 2.3N·m [Available For Size 24 Motor]

Parameter

1. Rated Voltage : DC24V +/- 5%

2. Resistance : 140Ω +/- 5%

3. Power consumption : 4.5W

4. Hold Torque : >2.3N·m

5. Insulation Class B

6. Insulation Resistance : >100Mohm (DC500V)

7. Dielectrical Strength : 1000 VAC for 1 second

8. Retraction time : 50ms

9. Release time : 30ms

10. Gyration gap : <1°

11. Emergency brake time : > 200 times

12. Lifetime : > 2,000,000 times

13. Noise Level : <60db